With the rapid development of the logistics industry and people's increasing emphasis on the safety of goods, a new type of packaging material is gradually entering the public eye-that is, shock-proof buffer air column bags. It has quickly become a popular choice in the industry with its lightweight design and excellent pressure resistance.

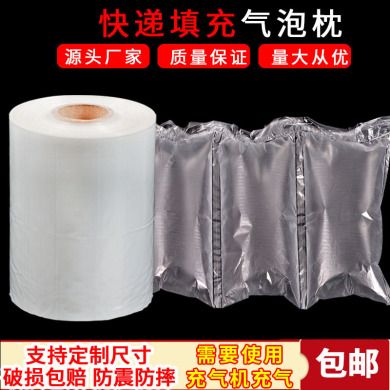

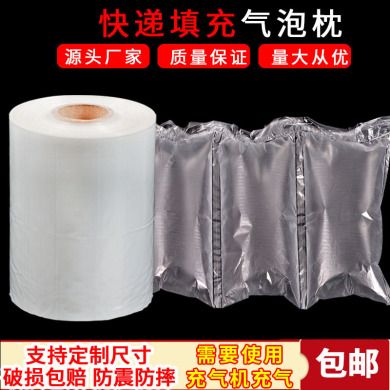

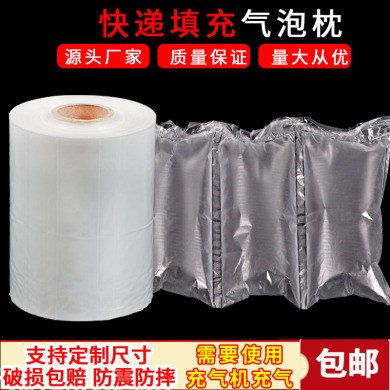

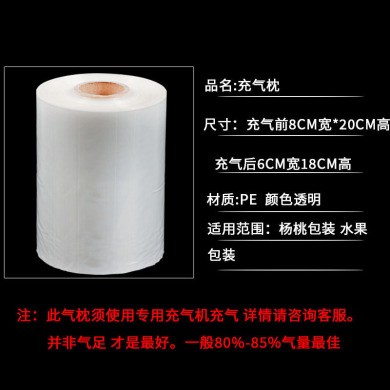

So what makes this seemingly ordinary bag so special? The answer lies in its subtle design. Each small air column filled with air is the result of scientific calculation; it is not only elastic enough to resist external impact but also not to break due to excessive expansion. And different from the problem that traditional foam is difficult to cut, this air column bag supports easy tearing by hand, which greatly facilitates the operator's wrapping work.

In addition to these basic advantages, its practicality has also been fully demonstrated. For example, in the delivery process of electronic products, it is often necessary to consider the risk that sensitive parts such as screens may be squeezed. At this time, if the use of ordinary paper boxes and adhesive tapes obviously cannot meet the requirements, but if one or more layers of shock-proof buffer air column bags with different lengths and widths are built in, such hidden dangers can be completely eliminated. In addition, high-risk objects such as glassware have benefited a lot, and every vulnerable link can be covered and reinforced.

In order to verify the authenticity of the above statement, the researchers specifically conducted a comparative test of simulated drop experiments for different types of loads. The results show that the damage rate of goods equipped with such protective measures is much lower than the numerical level of goods without any protective measures, whether under the condition of free fall to hard ground with a height of more than two meters or under repeated superimposed vibration environment. This series of detailed and reliable data undoubtedly provides consumers with strong confidence support.

of course, even the best things need to be learned how to use them in order to maximize their effectiveness. friends who come into contact for the first time may find it a little complicated, but it is not! Just follow the instructions in the instructions to complete the vacuuming and exhausting action in sequence (it will be easier and faster if it is an automatic version of the equipment), and then place the objects to be packed securely in the reserved gap for compaction to form a tight seamless overall combination form. The whole process is straightforward and time-consuming.

It is worth mentioning that while pursuing efficiency, we should also pay attention to environmental protection issues. Compared with those non-degradable disposable plastic products, the shockproof buffer air column bags that can be recycled and reused and made of green, environmentally friendly and pollution-free raw materials are obviously more in line with the direction of sustainable development. This is also the deep-seated reason why more and more enterprises are willing to take the initiative to choose it.