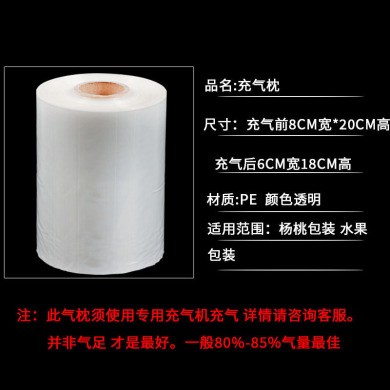

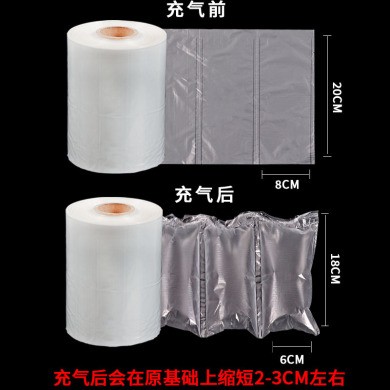

Redefining Logistics Protection Standards | Revealing the New Generation of Intelligent Cushioning Packaging Solutions

In the past, traditional foams have been the primary means of preventing shipping damage. However, with the rapid development of modern logistics industry and technology iterative upgrade, the old way has been unable to meet the growing security and efficiency requirements. With its intelligent structure design concept, the newly launched shock-proof cushion air column bag has successfully got rid of the excessive dependence on external cartons and opened a new era of professional shock-absorbing packaging.

This technology, which is based on the results of a large number of physical model calculations, not only has excellent seismic resistance, but also achieves the best energy absorption effect through precise control of gas distribution, so that every corner can be guaranteed with uniform and stable supporting force.

Master loading and unloading skills in one minute | How can tearable design rewrite the efficiency formula of warehousing operation

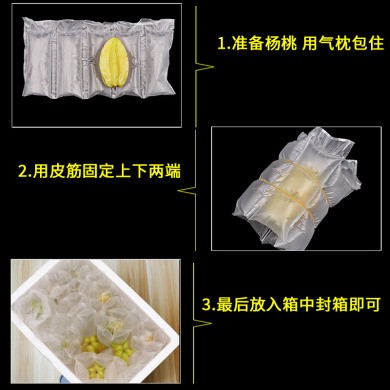

Different from the common hard-to-disassemble products on the market, this air column bag is specially added with a humanized controllable fracture edge treatment process, which realizes the quick opening function with bare hands without affecting the overall packaging firmness.

in the actual operation process, the bag opening action can be completed without the aid of scissors or other auxiliary tools, which greatly simplifies the operation complexity of the manual handling link while retaining sufficient airtight performance to resist external impact. Statistical analysis shows that such improvements can increase the speed of the entire packaging process by more than 40%.

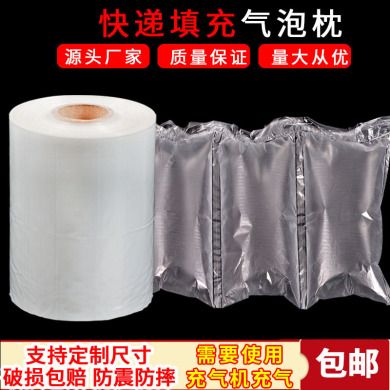

seismic laboratory data speak | filled bag coil structure against transportation risk of the three major killer

in order to deal with various potential threat factors that may occur during the long-distance freight transportation, the researchers specially set up a triple defense system for this device: firstly, the dynamic slow-release space formed by filling air inside is responsible for eliminating the negative effects caused by continuous oscillation; Secondly, a reinforced annular rib structure is arranged around the circumference to conduct the pressure load in the concentrated stress area back and forth; finally, the weather-resistant tough film material is selected to resist aging deformation caused by temperature changes.

This series of carefully arranged function combination together to build an indestructible security barrier, even if it encounters violent shaking, it will not easily cause damage to goods.

e-commerce sellers must see the strategy | talk about the importance of scientific packaging from 90% drop in damage payout rate

the head of a well-known online store specializing in consumer electronics revealed in an interview that the quality dispute cases returned by customers in just three months since the replacement of this new environmentally friendly airbag cushioning system have almost zero.

Compared with the high after-sales expenses caused by frequent product bumps and scratches before, the current situation is very different-not only saves a lot of capital investment, but also wins the wide praise and trust of consumers, thus further consolidating the market leading position.

Environmental protection answer sheet under green circular economy | Analysis of the secret formula of sustainable development buffer materials

In addition to excellent performance, another highlight of this product is that it is made of biodegradable friendly ingredients, so even if exposed to the external environment for a long time, it will gradually restore to the original substances of nature over time without causing lasting environmental pollution burden.

plus the support of multiple opening and closing locking mechanisms, a relatively perfect resource recovery and reuse chain is formed. according to the statistical calculation results, the carbon emission of each independent unit in the whole life cycle is reduced by about 70% than that of the original method. it is a model work that truly achieves win-win development with both economic benefits and social responsibilities.